As the frequent reader of this blog will know, I am a great fan of DIY and makerspaces.

I have visited Club Eclectic, Orange Hours, Republikken and even done #Hack4dk. All of them have most kindly welcomed me (and my camera) with equal open arms and minds.

However, none of this would happen without loads of hard work from the people who puts hours of effort into creating a real makerspace. The home of the Orange Makers in Roskilde is a fine example of this.

Home Sweet Home (of the Orange Makers) in Musicon, Roskilde

Since my latest visit to the big halls in Musicon many things have improved. There are much smaller and cosy rooms now, including electric heater and more people to make the guest feel at home. Check out the cool laser cutting lamps with the logo on. Not to mention the fact that Orange Makers hosted the biggest Makerfestival in Northern Europe with Made back in August 🙂 Thumbs up for this! (If you do not believe it, have a look for yourself at CPH:DOX.)

This night my visit had another purpose. I wanted to learn more about 3D printing. This is a subject, which has had my interest for about a year, but I have never really been able to understand how it works. Therefore, I decided to join a 3D printing workshop along with a few other makers. Serious fun 4 free.

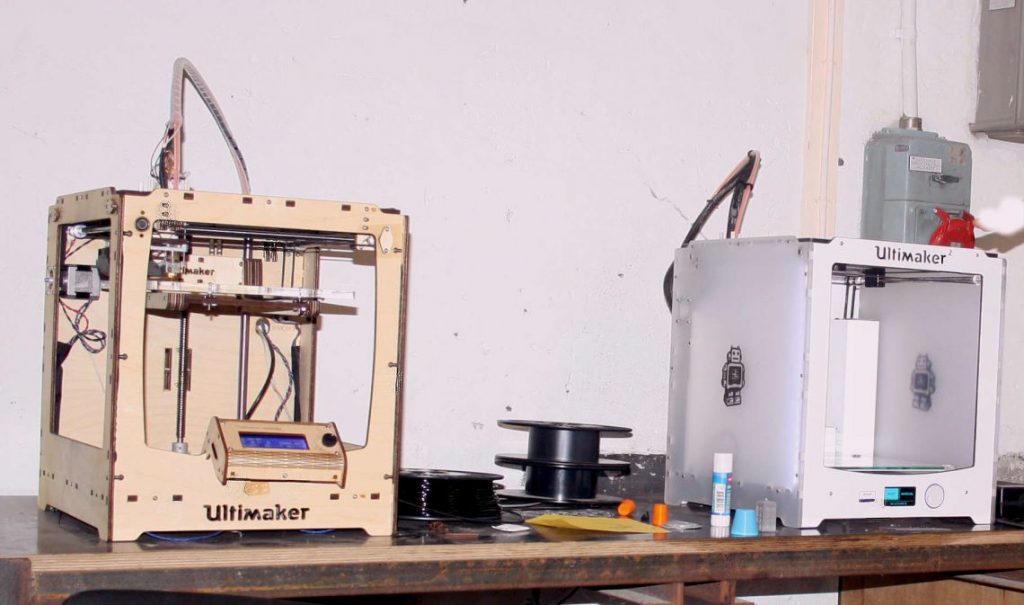

Note the shining white 3D Printer at the table to the left in the back.

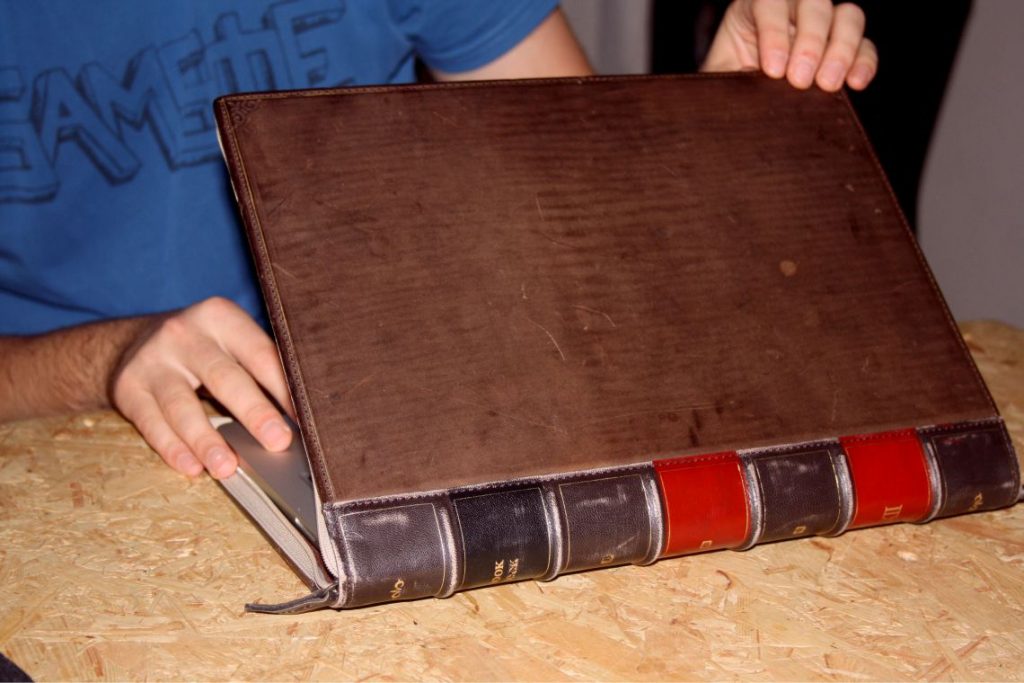

No home without leather-bound books. This maker has taken the idea a step further and covered his laptop in this old-fashioned style.

Down to business, we were introduced to the 3D Printers from Ultimaker. The one on the left is the first cheap promo model, whereas the one on the right is a real beauty to a maker’s desire.

Design engineer Morten Ydefeldt shows us the ropes on the art of printing. Or rather, the art of designing a print, because it is in the design the hard part is. Once you have drawn and dragged your object in the computer program, it is easy-peasy to save it on the SD-card and start printing. As Morten explains, the individual computer designs make 3D printing very good for creating unique products, e.g. in medical business for artificial limbs, which will fit the individual patient completely. And as long as you think about an object as consisting of many similar minor objects, it is actually not that hard to create a design. Just think about this neon tube as 2 similar ends with the same general content all the way through.

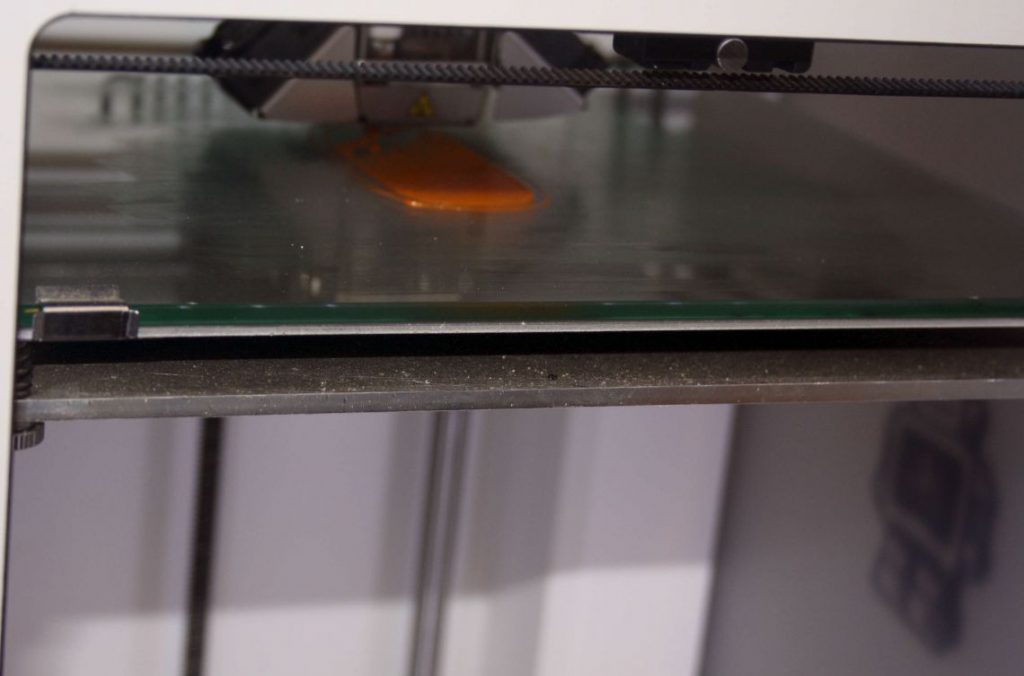

3D prints are really a bunch of plastic threads on top of each other, and that is why it is important to print on a non-slippery ground. That is why Morten puts a bit of glue on the glass plate, before he starts printing.

The printing material is heated to about 220 degrees Celsius. It consists of 2 types of thread; ABS, which is hard solid, or PLA, which is softer and made from corn waste. Eager to demonstrate how fast it is possible to print Morten made the print a bit messed up … but you can imagine what it might turn out to be.

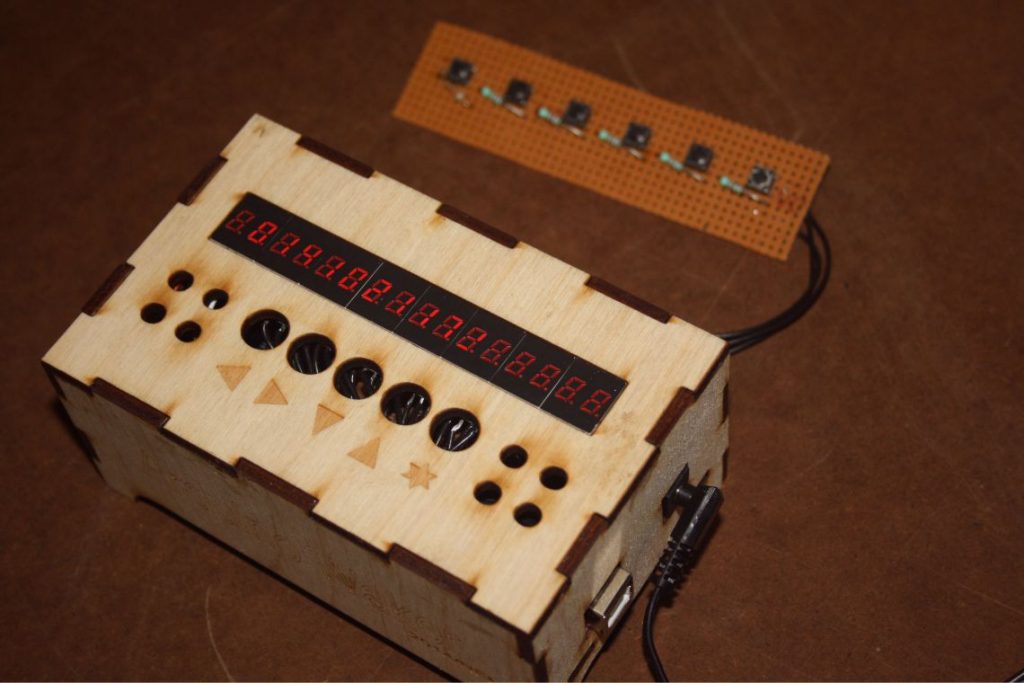

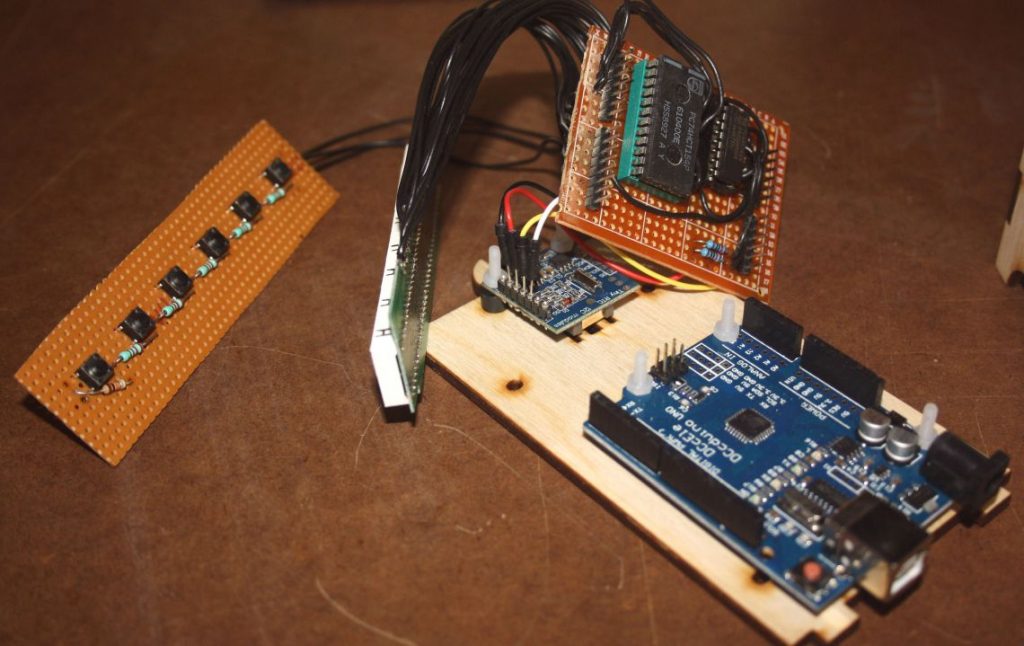

Nevertheless, 3D printing is not all that happens at the Orange Makers. Their other big issue is laser cuttings. I came across this homemade alarm clock – made in Arduino electronics.

Quite an impressive display – in case you are that tired that you do not remember which year, month or date you have woken up to (!) Without the cabinet, it looks like this:

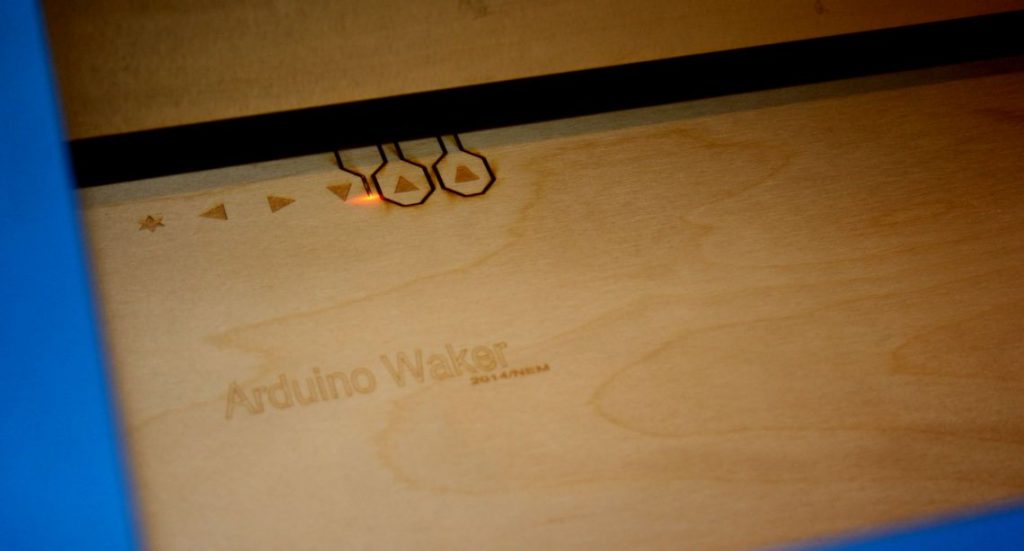

Returning to the cabinet, it is made by the wonder of laser cuttings. The creative maker has drawn his design in the computer, puts in a thin wooden plate and pushes the button on the laser cutter. Soon the machine starts to engrave the text and buttons to the front of the alarm clock. After engraving, it cuts out the pieces of wood to make it ready for use.

I would be proud of this fine homemade object … but actually, the maker could not wait to tear it apart again! It is not the product itself, but the making of it, which is fun, he explains. Well, I guess this is what defines a true maker 🙂

Settings, back, forward, up and down. The laser cutter creates the buttons of the Arduino alarm clock.

Are you a true maker? If that is so, you should join Orange Makers. They are finally ready to leave the parental nest of Roskilde Festival. In a few days they will have their statutory general meeting, and anyone who wants to keep the Orange Makerspace alive is welcome. Even though all members will have to pay a minor fee to cover materials in the space, I am sure you will still be welcome to join free events, workshops or the ordinary Maker Days Wednesdays and Thurdays.

Read more about Orange Makerspace’s statutory general meeting. (In Danish).

Read all about the Orange Makers.

This night I left with a souvenir of this laser cut bird – and a feeling of a new beginning.